Proven Mist Collectors Years Ahead of our Competitors!

- Guaranteed Maintenance Cycles of 1-3 years

- Guaranteed Efficiencies Below 0.05 mg/m3 (exceeds OSHA standards)

- Continuous Duty 24/7

- High Pressure Oils & Coolants

- Heavy Oil and Smoke Concentrations

- Cold Headers, Die Casting, Forging, Turning, Milling, Screw Machines, Grinding, CNC, Hydromats, Heat Treating, Transfer Lines

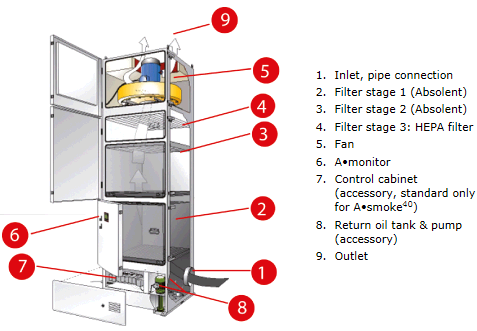

Unique Filter Cassettes

Absolent is one of few companies in this line of business that has specialized in the filtration of air containing wet particles. This has given us the opportunity to develop a filter cassette that offers a long useful life with consistently high collecting efficiency.

Mist oil mist filters are well suited to applications such as:

Grinding (cutting fluid emulsion)

Turning (cutting fluid emulsion)

Milling (cutting fluid emulsion)

Electrical discharge machining

Machining, using straight oil and moderate loads

Why use an oil mist filter?

Oil mist is hazardous to your health. Oil mist causes slippery floors and collects dust on machines and walls. Official regulations are becoming increasingly stringent. It is, therefore important to invest in equipment that will comply with future requirements.

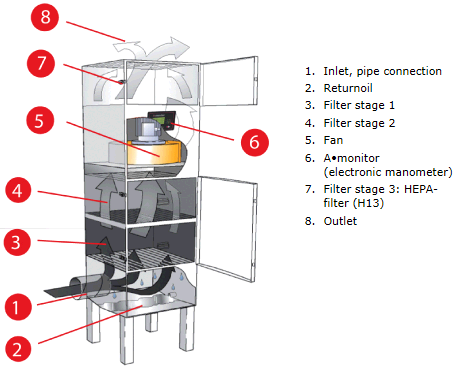

Why use an oil smoke filter?

Oil smoke is hazardous to your health. Oil smoke causes slippery floors and collects oil and dust on machines and walls. Oil smoke can lead to coating in ventilation pipes, a potential fire risk, and in heat exchangers, so reducing the efficiency of heat recovery. The cutting oil which drains from the filter can be reused. The amount of oil smoke polluted air discharged must not exceed the prescribed limits. To learn more about ACR, Inc.‘s mist collection systems available in Columbus and Garden City, IN, contact us today! We are Indiana’s number-one supplier of mist collectors, wet collection systems, dust collectors, and beyond.